Why All Gearboxes Are Not the Same — Even If They have the same external dimensions

Understanding the hidden differences behind mechanical power capacity

In the electric motor market, comparing two products often starts with numbers — first the power, poles, efficiency class, frame size — before discussing the intrinsic quality that makes one brand more reliable than another.

With gearboxes, however, the comparison is far more complex. What really defines a gearbox is not only its mounting dimensions or external design, some even just refer to the output shaft diameter (do they also compare two cars according to the tyres diameter?) , but its power capacity, or in more technical terms, its service factor.

Unfortunately, some buyers still look only at the interchangeability of mounting dimensions, assuming that if two gearboxes share the same footprint, or output flange, or shaft, they will perform equally. That assumption is dangerously wrong.

Two units might fit the same shaft and flange, yet have completely different torque capacities, durability, and efficiency.

When identical shapes hide different strengths

Even a simple look at the weight of a gearbox can reveal something about its internal design — heavier often means thicker gears , bigger or more bearings, and a more robust housing.

But this is only part of the story.

An important difference lies in the design philosophy behind the gears themselves — and in the engineering compromises that many manufacturers have made over the years.

The logistics-driven compromise

To simplify their logistics, many European gearbox makers — following the example set by the world leader — decided years ago to minimize the number of gear part codes used in their production.

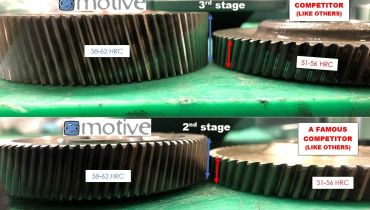

Specifically, in a three-stage gearbox, they standardized the second and third stages (the four largest gears) across multiple ratios and frame sizes.

This approach allowed them to keep a smaller number of pre-assembled “modules” on the shelf.

For companies relying on external assembly centers, it seemed a practical solution: fewer parts to manage in stock, quicker assembly, and, even the temptation to skip final testing.

However, this convenience came with a hidden cost.

Because the same internal gears are reused in multiple ratios, the maximum transmittable torque becomes limited by the weakest stage in the chain.

In other words, the design creates load capacity bottlenecks — service factors vary irregularly across ratios, and some ratios are inevitably less robust.

Let’s explain it with 2 graphs, where the average kW capacity of the 3 stages of 2 different gearboxes is the same, but the distribution is not.

The first graphs shows what happens in a gearbox when the kW capacity is badly distributed, due to the fact that the requested final ratio is assembled by a minimized number of gears codes in the second and third stage

5kW is the max kW of the 3rd stage at Sf 1, therefor 5kW is the whole gearbox max capacity at sf 1, in this case

The next graph shows instead an example of what happens when you have the right gears to choose from for the second and third stage, and you can optimize the distribution of the max kW capacity among the 3 stages

Result: 9kW is the whole gearbox max capacity at sf 1

The false promise of warehouse simplification

Paradoxically, this system didn’t even achieve the illusory goal.

External assembly centers that wanted to reduce stock actually ended up keeping more components: extra housings, flanges, shafts, bearings, inside the pre-assembled submodules.

And about codes and stock simplicity? Today, modern digital logistics and informatic tools could have solved these challenges more elegantly — without sacrificing mechanical integrity.

Why Chinese gearboxes are so cheap

Many Chinese manufacturers went a step further by copying such design completely — same external shape, same ratios, same gear data.

This uniformity created huge economies of scale: thousands of identical gears produced at once, used by dozens of factories.

But that’s also the limit of this concept: efficiency in production comes at the expense of power capacity, not just for the bottleneck of the second or third stage parts codes minimization.

The economy of parts and processes has become the top priority for many manufacturers — sometimes pushed to such extremes that we have even seen gear producers mount bevel gears by “ear” or by “feel,” without using any measuring instruments at all during assembly.

The Motive-ated difference

At Motive, we don’t follow that path.

We designed our own gears geometry, with optimized mesh data to maximize power capacity and lifetime.

We decided to distribute the mechanical effort equally among the reduction stages, by using a greater and optimized number of gear combinations.

We then combined this design choice with the use of keyed shafts instead of the cheaper interference-fit system, giving the possibility to assemble, disassemble, and reassemble any gear.

In addition, we developed systems that share data between our ERP and MotiveLabs, making it easy to automatically get the bill of materials.

Finally, every MotiveLab is equipped with test benches that monitor efficiency, oil losses, speed, and even the presence of all keys before a gearbox is approved.

Our goal is not to imitate, but to outperform — ensuring that each gearbox delivers its declared torque continuously, safely, and with generous margins.

Today, perhaps because they are the newest ones in the market, or perhaps because no compromises were ever accepted in their design — we can confidently say that our ROBUS, STON, and ENDURO series are at the same external size, the highest load-capacity gearboxes on the market

_370.png)

_370.png)